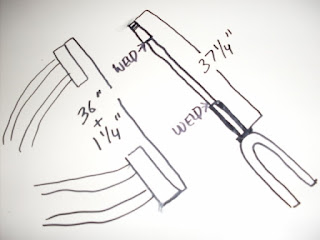

In this post i will be showing you 2 ways to attach handlebars to a cut down upside down fork,and also the start of a way to build a new type of bike steering wheel. Please check out my previous post about steering couplers,and PART B of the SURF WOODY project tallbike. The first way is to take a pair of drop down bars ( steel OR aluminum ), and bend them so the ends are parallel. Then cut them in half with a pipe cutter.If you're using steel bars you can just push them into the fork tubes adjust them by rotating to where they feel comfy and weld them in place !!!! YES IT"S JUST THAT EASY !!!!!!! You can either sand them down and paint them,OR put some cool bar tape on them. If your using aluminum bars

you will need to cut a 1/8" wide 1" long slot in the tops of the fork tubes and attach 2 appropriate sized seat post clamps.This is a good way to go because you can always adjust them later.The second way is to get a couple matching 22.2 bar stems ( I am using 2 mini 4 bolt BMX stems from some 16" parts bikes ). Make 2 split tubing spacers by finding some tubing that fits INSIDE the fork tubes and OUTSIDE the stems shaft.Tap the tubing down into the fork tubes as far as it will go,then mark it with tape as shown. Pull the tubing out and cut 2 pieces that length.Now cut a 1/8" slot along the length of both pieces. Now push the split tubing pieces ito the fork tubes,followed by the h-bar stems ( you may have to put the stems on the bars beforehand depending on what type of stems you're using ).There are several types of bars that will work here. Basically anything that has a wide,straight middle section,like inverted dropdown bars ,cruiser bars,or straight MTB bars,etc. When using anything other than the BMX 4 bolt stems you will have to use split tube spacers on the clamp part of the stems .Just cut a couple of pieces of tubing about a 1/4" wider than the clamp part of the stem and then cut them in half lengthwise to make it possible to slide them in place. These pieces could also be welded in place so the bars won't rotate when there is up or down pressure apllied to them while riding. Now adjust everything to a comfy position and tighten it all down and your done !!!! The steering wheel version will be covered later in a post for the SURF WOODY project,but you can get a good idea from the picture how it will go together.Any questions,comments,criticisms ( positive or negative ),E-mail me at

omahgarsh@gmail.com I'd love to hear what you have to say !!!!!!!!

Any questions,comments,criticisms ( positive or negative ) E-mail me at omahgarsh@gmail.com I'd love to hear what you have to say !!!!!!!!

Any questions,comments,criticisms ( positive or negative ) E-mail me at omahgarsh@gmail.com I'd love to hear what you have to say !!!!!!!! Any questions,comments,criticisms ( positive or negative ) E-mail me at omahgarsh@gmail.com I'd love to hear what you have to say !!!!!!!!

Any questions,comments,criticisms ( positive or negative ) E-mail me at omahgarsh@gmail.com I'd love to hear what you have to say !!!!!!!!